Printing technology has advanced in many ways, and one of the most efficient methods is direct thermal printing. If you’ve ever received a receipt from a store or a shipping label from a courier, you’ve likely seen this technology in action. But you might be wondering: how do direct thermal printers work?

In this guide, we’ll break it down step by step so you can understand the process, the benefits, and when to use direct thermal printing.

🖨️ What Is a Direct Thermal Printer?

A direct thermal printer is a type of printer that does not use ink, toner, or ribbons. Instead, it relies on heat-sensitive paper that changes color when exposed to heat from the printer’s printhead.

- ✅ Commonly used for receipts, labels, and tickets

- ✅ Popular in retail, logistics, healthcare, and hospitality

- ✅ Known for being cost-effective and low-maintenance

This makes them different from inkjet or laser printers, which require cartridges and toners.

🔍 How Do Direct Thermal Printers Work?

So, how do direct thermal printers work in practice? Let’s look at the step-by-step process:

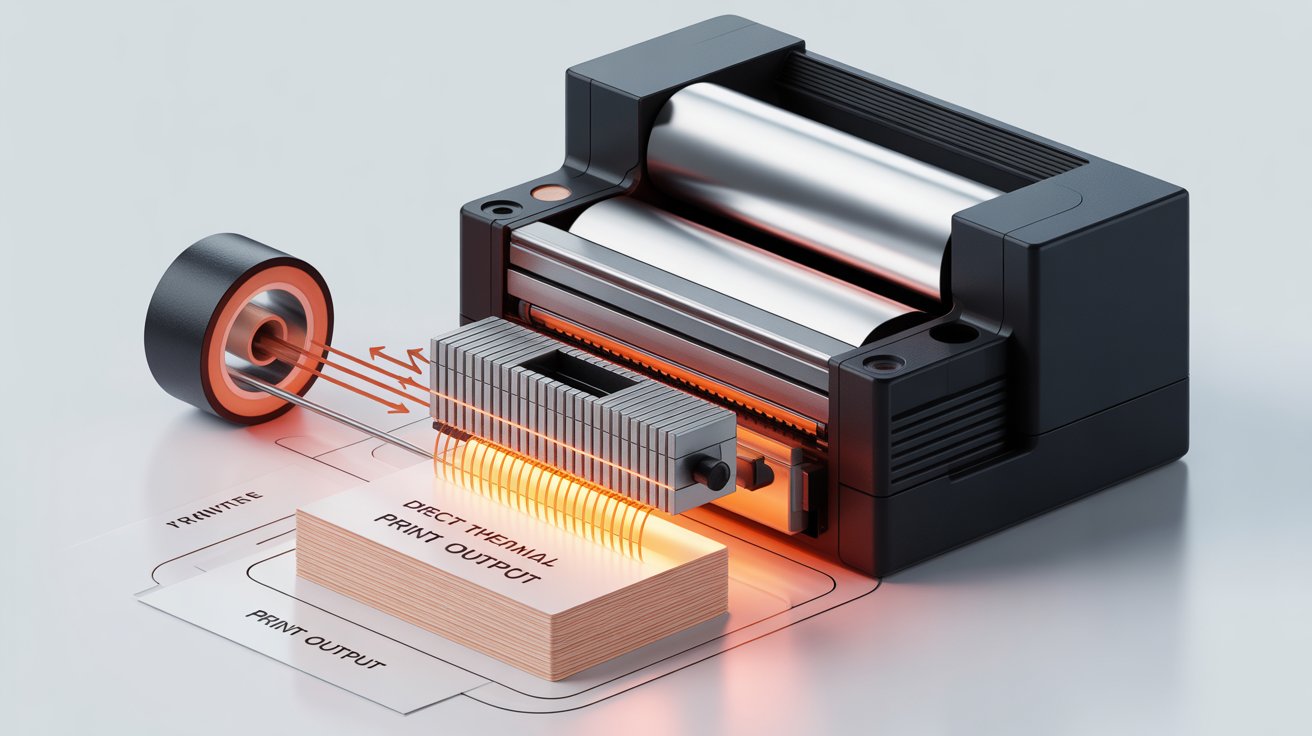

Step 1: Heat-Sensitive Paper

Direct thermal printers use special coated paper. This paper contains a chemical layer that reacts when exposed to heat, turning black (or sometimes other colors).

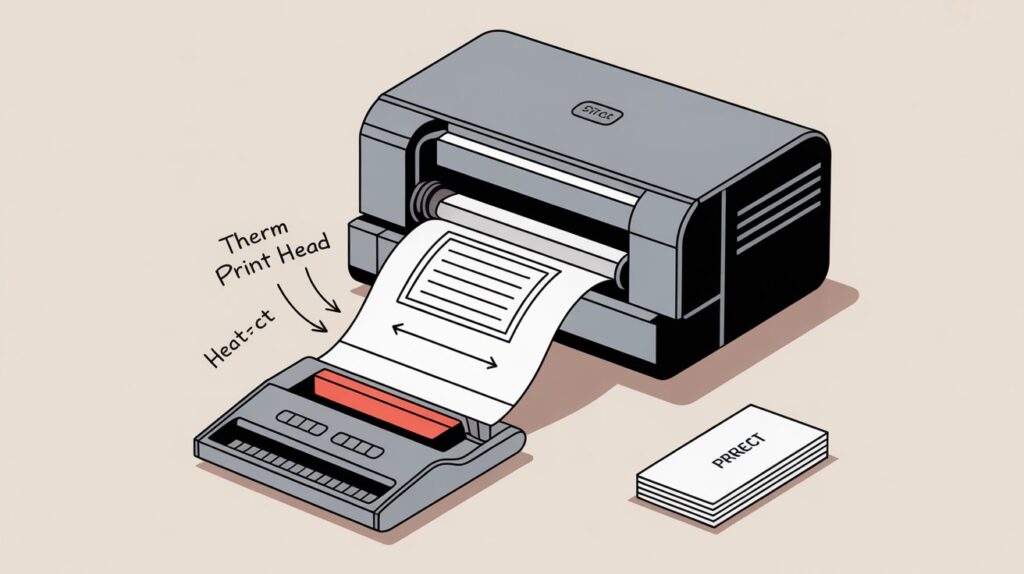

Step 2: Printhead Activation

The printer contains a thermal printhead made up of microscopic heating elements.. When activated, these elements apply heat to specific spots on the paper.

Step 3: Image Formation

As the paper passes under the printhead, the heated areas darken, creating text, barcodes, or images.

Step 4: Output

The final result is a crisp, sharp print — no ink, no mess, and no waiting for drying.

👉 In simple terms: heat + special paper = printed image.

🆚 Direct Thermal vs Thermal Transfer Printers

It’s important to distinguish between direct thermal printers and thermal transfer printers, since they are often confused.

| Feature | Direct Thermal Printer | Thermal Transfer Printer |

|---|---|---|

| Printing Material | Heat-sensitive paper | Standard paper with ribbon |

| Ink/Toner Needed | ❌ No | ✅ Yes (ribbon) |

| Durability | Fades over time | Longer-lasting prints |

| Common Use | Receipts, shipping labels | Asset tags, product labels |

| Cost | Lower | Higher (due to ribbons) |

👉 If you need short-term prints like receipts, use direct thermal. If you need long-lasting, durable labels, thermal transfer is better.

🌍 Why Are Direct Thermal Printers Important?

Understanding how do direct thermal printers work also helps you see why they matter in many industries.

- 📦 Logistics & Shipping – Used for barcodes, shipping labels, and warehouse tracking

- 🛒 Retail – Perfect for receipts and product price tags

- 🏥 Healthcare – Commonly used for wristbands and lab test labels

- 🎟️ Events & Entertainment – Great for tickets and passes

They play a big role in speed and efficiency, especially where printing needs to be fast and low-cost.

✅ Advantages of Direct Thermal Printers

- 🖨️ No Ink or Toner Required – Saves money on supplies

- ⚡ Fast Printing Speed – Ideal for high-volume printing like receipts

- 💰 Low Maintenance – Fewer moving parts and consumables

- 📏 Compact Size – Fits easily on counters or desktops

- 📦 Great for Labels – Works seamlessly with shipping and barcode systems

❌ Disadvantages of Direct Thermal Printers

- ⏳ Prints Fade Over Time – Not suitable for long-term documentation

- ☀️ Heat Sensitive – Exposure to sunlight or heat can damage prints

- 🎨 Limited Colors – Mostly black-and-white printing

- 📜 Requires Special Paper – Can be more expensive than standard paper

📌 Examples of Direct Thermal Printer Use

Here are some real-life examples where you’ll see them in action:

- 🛒 Retail Stores – Printing receipts at checkout

- 📦 Logistics Companies – UPS, FedEx, DHL shipping labels

- 🏥 Hospitals – Patient wristbands and lab labels

- 🎟️ Movie Theaters – Tickets and passes

If you’ve ever handled a store receipt that faded after a few months — that’s a direct thermal print!

💡 Common Mistakes to Avoid

If you’re new to using direct thermal printers, here are some mistakes to watch out for:

- ❌ Using regular paper instead of thermal paper

- ❌ Exposing labels or receipts to direct sunlight

- ❌ Forgetting that prints fade and storing them long-term

- ❌ Confusing direct thermal with thermal transfer

📲 Related Questions:

Since this technology is often mixed up with other printer types, let’s connect it with related concepts:

- What is a thermal printer and how does it work? → A broad category, includes both direct thermal and thermal transfer.

- How does a thermal printer work? → Applies heat, either straight onto the paper or through a ribbon.

- How do thermal label printers work? → They print shipping/warehouse labels using direct thermal or transfer methods.

- How do thermal printers work without ink? → They use heat-sensitive paper instead of ink.

- How does a direct thermal printer work? → Exactly what we’ve covered — heat + thermal paper.

🙋 FAQs

1. How long do direct thermal prints last?

Direct thermal prints typically last 6 months to 1 year, depending on storage conditions. Exposure to heat, sunlight, or friction can shorten their lifespan.

2. Do direct thermal printers need ink or toner?

No. They only need heat-sensitive thermal paper, which reacts to the printhead’s heat to form images.

3. What’s the difference between direct thermal and thermal transfer printing?

Direct thermal uses heat-sensitive paper only, while thermal transfer uses a ribbon to transfer ink onto paper. Direct thermal is cheaper, but thermal transfer lasts longer.

🎯 Final Thoughts

Now you know how do direct thermal printers work — they use heat and special paper to create fast, clean, and cost-effective prints without ink or toner. While they aren’t suitable for long-term documents, they shine in industries like retail, logistics, healthcare, and events.

If you want low-cost, efficient, and low-maintenance printing, a direct thermal printer may be the right choice for your needs.